Near-Zero Wastewater Discharge

E4-Aps

Background

Leveraging extensive experience and expertise in plastic recycling, Boretech brings you a leading wastewater treatment solution.

The energy-saving, low-emission, and efficient process minimizes operational energy consumption, optimizes production efficiency, and boosts resource utilization.

We help plastic recyclers to reduce costs while enhancing sustainability, fostering a greener, more efficient production model.

Together, let's protect resource on earth and stride towards a brighter future.

Feature

E4-Aps

Easy 4(for)Aqua purification solutions

[E4 = Excellent + Ecologic + Economic + Efficient, achieves near-zero wastewater discharge]

√The energy-saving, low-emission, and efficient process minimizes operational energy consumption, optimizes production efficiency, and boosts resource utilization.

√With the smart control module integrated in the process, the management can monitor factory operations in real time.

√Various process options are available to align with customers' needs and ESG goals.

√The exceptional process is streamlined and optimized.

√The pH of wastewater is reduced to 6.5-7.5, the removal rate of suspended particles and oil can reach 99%, the COD removal rate can reach 98%, and the BOD removal rate can reach 98%.

The standard sewage treatment system processes provided by Boretech: anaerobic and biochemical process and physical and biochemical process, can meet the national wastewater discharge standard III.

In addition, we also have optimization modules to choose from, including MBR process module, Desalination process module and Evaporation process module, which combined with the standard module can achieve wastewater discharge standard I, 80% for recycling, near-zero discharge.

UF+RO process can also reach tap water quality.

Description

The wastewater of washing line is mainly from hot washing with detergent and rinsing section.

For every ton of PET flakes cleaned, approximately 0.13 tons of wastewater discharged from hot washing and about 3 tons of wastewater discharged from crushing unit are generated.

Anaerobic and Biochemical process

Sludge production reduced by ~30%. Carbon emissions reduced by 20-25%. Operation cost <$1/m³.Technology cooperation with well-known colleges.

√Larger flow rate; easier to process high concentration of organic compounds such as polysaccharide, protein, etc..

√Lower sludge disposal cost, owing to low sludge yield.

√Lower energy cost, owing to the reuse of the generated energy.

√Larger footprint and more limitations during operation.

√Lower operation cost in the long term.

Physico-chemical and Biochemical process

Start operation <2 weeks.Affordable SS fluctuation up tp 50%.Facility construction cost economy.Removal by air flotation up to 90%.

√Lower flow rate; easier to process low concentration of organic compounds.

√Stronger ability to resist water quality fluctuations.

√Stunning performance in processing high concentration of suspended solids and oily compounds in the wastewater.

√Lower footprint.

√Lower investment.

√Easier for operation and maintenance.

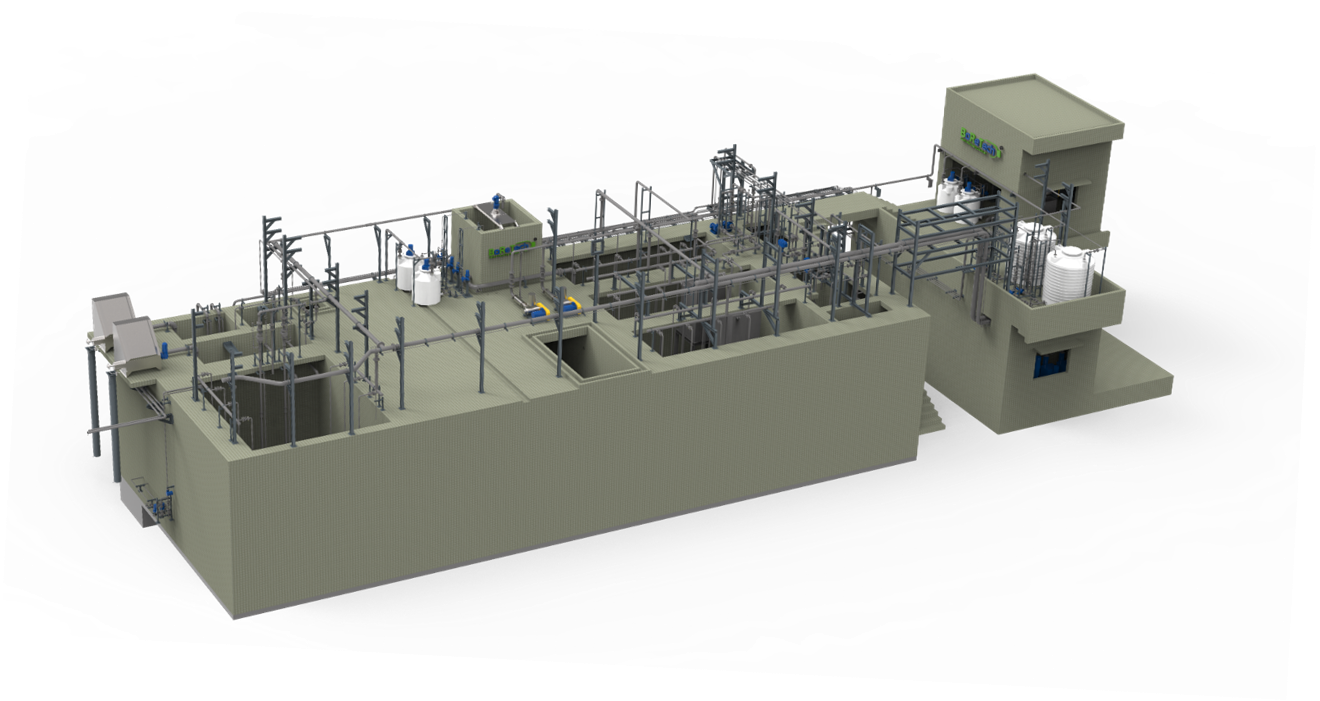

3D Layout

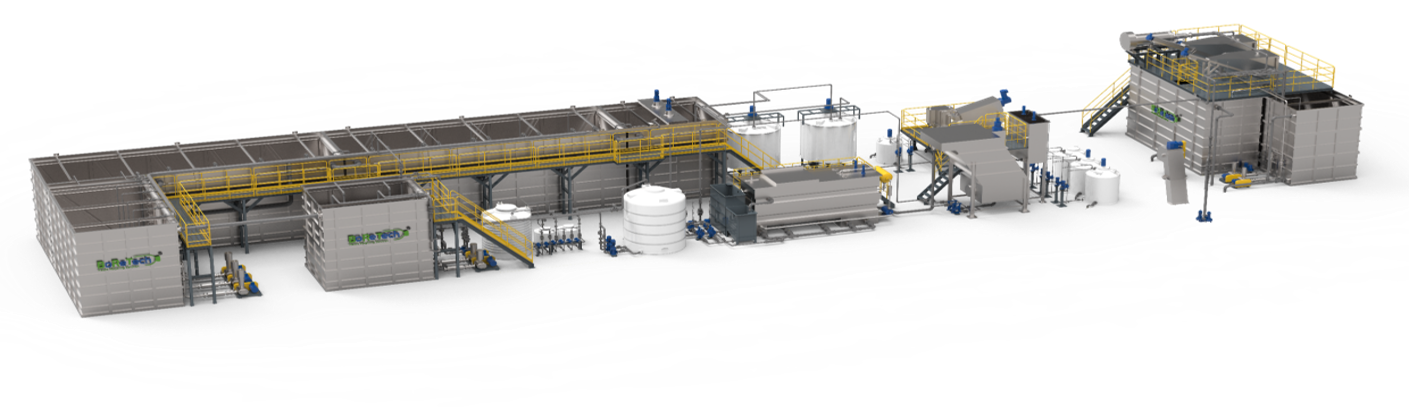

Reference